Welcome to the first of our series of CTS blogs focused on something we’re pretty hooked on: Technology.

It’s changed the face of fishing and rod design, and it’s what we live and breathe at CTS. When the world is looking for faster and cheaper ways of producing fishing rods, we’re laser-focused on the science and art of doing it in the very best way possible. Best design, best engineering, best materials.

Our series will unravel for you, the technical terms often used in fishing and rod building circles. No jargon or waffle – just plain interesting stuff about the how and the why of rod design, and what rod blanks are made of.

We’ll start today with Modulus and Strength. They’re two quite different things, but are often confused as being the same.

Modulus

When an angler asks for a strong rod, what they actually mean is they want a stiff rod. That’s where modulus comes in.

Modulus is commonly referred to as the ‘stiffness’ of a material. It’s possible to have very stiff materials that aren’t exceptionally strong (like window panes), and conversely, there are very strong materials that are not stiff (like rubber bungee cords).

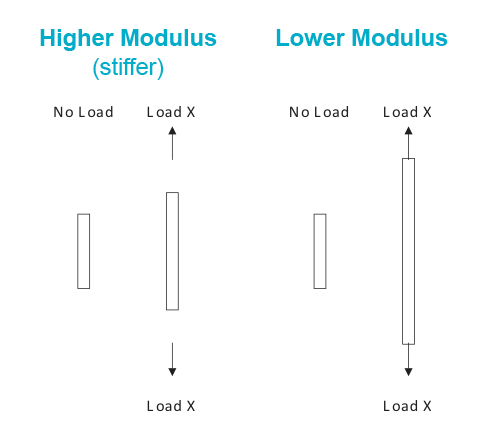

If you apply the same load to materials of low and high modulus, the lower modulus materials will stretch further.

In the diagram at left, you’ll see that the same load (X) applied to a high modulus and low modulus material causes the low modulus material to stretch (strain) further during loading.

Strength

Strength, on the other hand, is how much load the material will take before it fails (breaks). We define stress as being the load on the material, and strain as being the deformation when under load. Glass fiber can take a lot of load (stress) before failure, but stretches (strains) further than carbon during loading.

In engineering, generally, structures are designed to take load, but NOT to bend or flex. Like, say a beam in your house.

Fishing Rod Design

When it comes to designing fishing rods, the engineering requirements are quite unique, in that you’re wanting the rod to take a reasonable amount of load, but you’re also wanting it to bend. Designing high performance fly rods is both a science and an art, in that in addition to stiffness, load and bend, we also factor in the desired rod ‘action’ (we’ll cover ‘action’ in a blog of its own).

In our bigger rod series: A game rod demands a bit of bend so that it doesn’t punish the angler during a big fight – however, you don’t want it so soft that it’s unresponsive and doesn’t allow you to control the fight. If surf casting, you want your rod to bend because you’re effectively loading it like a coil spring to then deliver the load through the cast.

Weight

Unsurprisingly, weight is always an important factor in design. A stiff rod that weighs a lot isn’t desirable, and neither is a super light stiff rod that isn’t robust (strong). We are always aiming to achieve the perfect balance between strength, stiffness and weight in our designs.

Tension and Compression

A material’s strength can differ depending on whether’s it’s being pulled (stretched) or pushed (compressed). For example, concrete is very strong under compression, but less so under tension (pull).

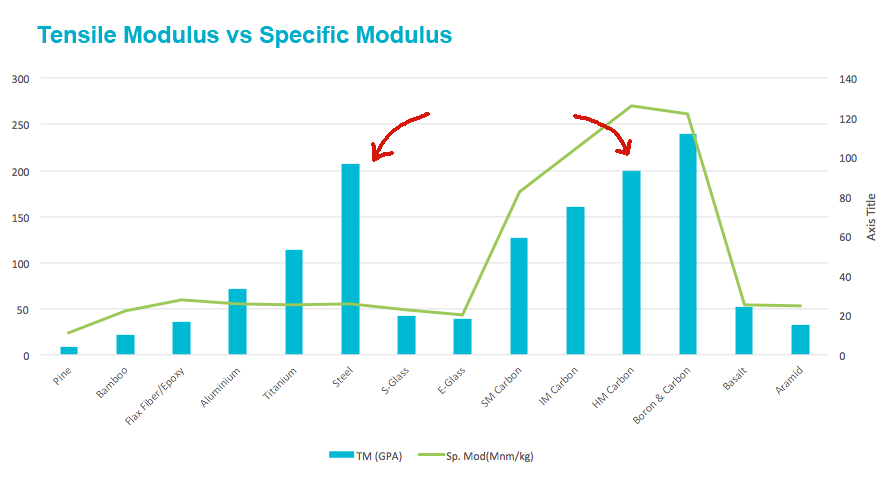

Tensile Modulus vs Specific Modulus

You can see in the blue bars at right, the tensile modulus (modulus under stretch or pull) of steel and High Modulus (HM) carbon are very similar.

But it is the Specific Modulus (green line) that highlights for us why we build rods out of carbon and not steel! Specific modulus = your stiffness divided by density (power-to-weight ratio). Steel is four times heavier than carbon, so its power-to-weight ratio is a lot less.

Thanks for reading. In our next blog, we’ll talk about the various different types of materials we use in carbon rods.

Stephen Pratt